the venerable Wells-Gardner K7000 had a tremendous run in the 80s and 90s as easily the most commonly produced video game monitor. at some point in the late 80s and early 90s however, another variation of the K7000 emerged to I would surmise ease some of the trouble of churning them out: the Zenith K7000A. the K7000A is probably most well known for having a unique flyback transformer, one that replacements can’t be had. fortunately it seems it’s more robust than Wells-Gardner’s model and doesn’t require frequent replacement. if you’re a game technician like me though, you’ll observe that Zenith’s design is laid out differently and is itself more robust. I don’t spend considerable time removing resistors to sand or reinforce connections on the Zenith model. the purpose of me writing this article though is to show that there possibly is a limitation in the design, not so much a flaw. I got several texts over the weekend saying a game was burning, and ownership narrowed it down to some games clustered together and had them turned off. it just so happened when I came in Sunday I chose the right one.

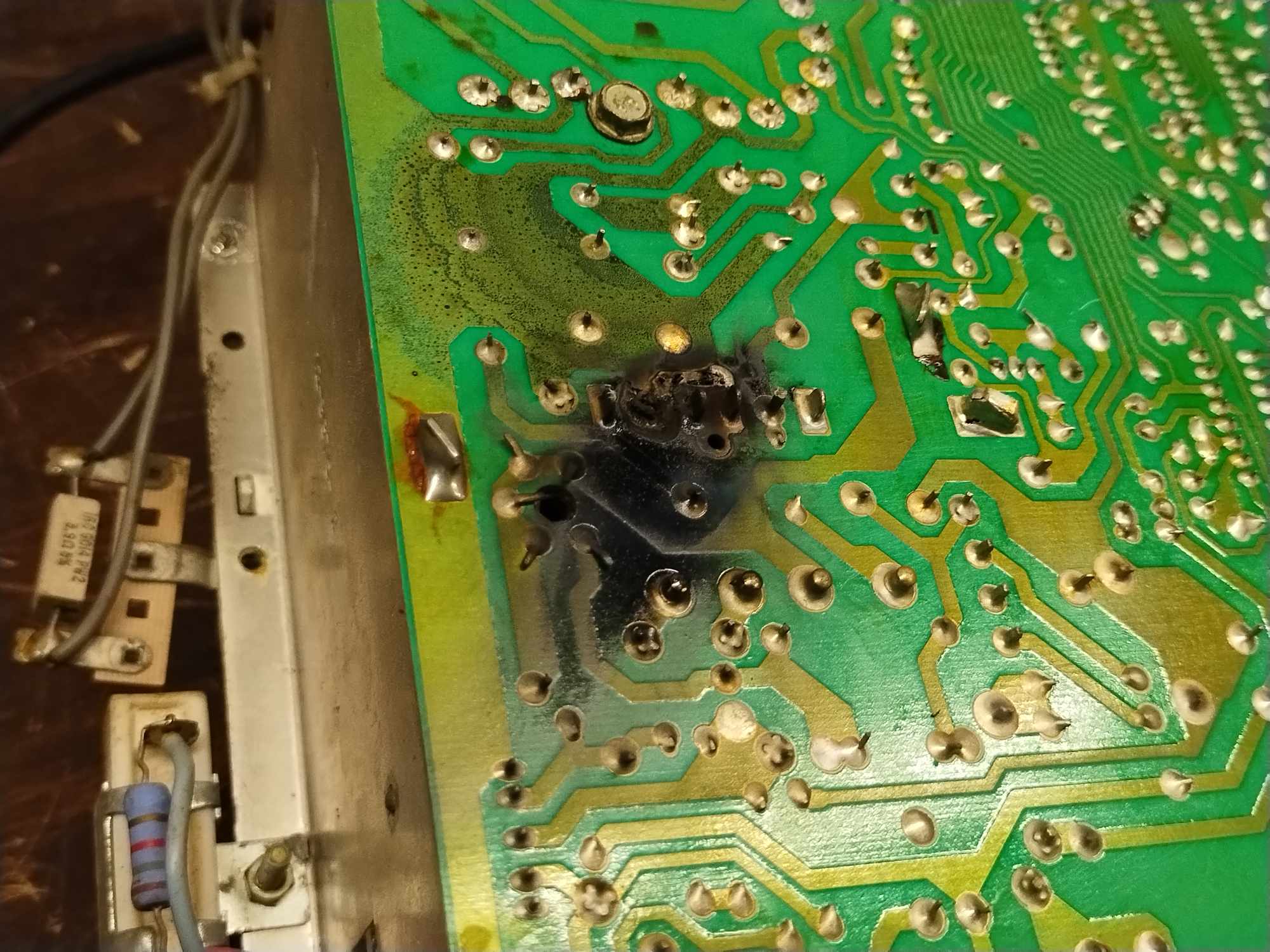

D18 is a part on the Wells-Gardner K7000 that I remove for cleanup, and to denote that I was there and did it, I mount the diode underneath when I’m done. on the Zenith K7000A however, the D16 and D18 parts are mounted to heatsinks where physically only one leg of the diode is soldered into the deflection board; the other end is connected to the heatsink legs. what I estimate happened here was the diode end solder broke down, which turns into increased resistance, and with increased resistance comes increased heat. D16 in this case burned a hole in the board. not something I’m unfamiliar with on any K7000. I’m unfamiliar with how the traces run on these, so it’s a good thing I had a decommissioned K7000A in a box to cheat off of.

the cabinet in general was utterly filthy, I elected to have the whole tube pulled to hit with the air compressor in back.

when I turned the game on I smelled a very familiar electronic barbecue aroma — I assumed this was a bad flyback, but I was wrong.

I gather this was the vertical IC supply voltage wire, I replaced it (now that I think about it maybe the vertical IC shorted too?)

here’s the other K7000A, I needed to see where I had to reconnect to. (notice how terrible the solder is)

the skidmark on the mounting tray.

functionality over aesthetics, I always said. while I was in the area I completely redid the solder to the yoke header pins and width coil.

left: D16, right: D18. to reinstall these I had to take out C36 (green critical safety cap in front) and C38 (brownish width cap in back) and they both tested good. I resoldered the cathode end legs on the top of the heatsinks too.

I neglected to mention the deflection board got washed in the utility sink, the neckboard and flyback were cleaned with Windex and paper towel.

now, will it blend? I have to finish replacing caps and probably would be beneficial to test the vertical IC also (not sure why that wire melted when the scorching fault was in the horizontal deflection section). I’ll update accordingly when I reach that point.

UPDATE: it blends! albeit with a minor complication. if you tapped on the monitor it would shut off and on. I was quite convinced I had everything solid except I neglected one item: the fuse holder. the metal fuse clips are starting to break more frequently on all K7000s and naturally I’m in another place that doesn’t have replacements. so I had to improvise with a plastic fuse holder with tabs (intended to connect wires) by soldering cap legs through the fuse holder tabs and then soldering the cap legs into the board. it’s entirely solid now with an observed 123.5V B+ (meaning the filter cap is fine)